Plate Heat Exchanger

ABSTRACT

Pasteurization is a killing method of pathogenic microorganisms e.g mycobacterium tuberculoses , salmonella by application of heat at 62ºC for 30 minutes or 72ºC for 15 seconds.

In this experiment, raw milk was pasteurized by using plate heat exchanger at 72ºC for 15 seconds and overall heat transfer coefficient of regeneration,cooling and heating mediums was calculated.Effectiveness of plate heat exchanger was measured by using datas obtained from experiment.Microbial succession of plate heat exchanger was investigated by using methylene blue indicator for color changes because of binding tendency of methylene blue on hydrogen atoms by changing color from blue to colorless.

CIP (cleaning in place) was carried out step by step after pasteurization by using water and special solvents (sodium hydroxide,water and nitric acid). After controlling the cleanless of the heat exchanger by using phenolphtalein indicator.If color changes to pink ,meaning that there is still NaOH in water.After alkaline threatment,nitric acid was used as disinfectant.

In this laboratory report,general principles of plate heat exchanger were mentioned and heat transfer coefficients of each section were calculated.

THEORY

A heat exchanger is used to transfer heat by the indirect method. Several different types will be described later. It is possible to simplify heat transfer by representing the heat exchanger symbolically as two channels separated by a tubular partition. Hot water (red) flows through one channel and milk (blue) through the other. Heat is transferred through the partition. The hot water enters the channel at a temperature of ti2 and is cooled to a temperature of to2 at the outlet. Milk enters the heat exchanger at a temperature of ti1 and is heated by the hot water to an exit temperature of to1. The temperature changes during passage through the heat exchanger are shown by the curves in figure 1 [1].

Figure 1.

Dimensioning data for a heat exchanger

The necessary size and configuration of a heat exchanger depend on many factors. The calculation is very intricate and is nowadays normally done with the aid of a computer. The factors that must be considered are :

• Product flow rate

• Physical properties of the liquids

• Temperature program

• Permitted pressure drops

• Heat exchanger design

• Cleanability requirements

• Required running times [2]

The general formula for calculating the required size (heat transfer area) of a heat exchanger is:

Logarithmic mean temperature difference (LMTD)

It has already been mentioned that there must be a difference in temperature between the two media for heat transfer to take place. The differential temperature is the driving force. The greater the difference in temperature, the more heat is transferred and the smaller the heat exchanger needed. For sensitive products there are, however, limits to how great a difference can be used.

The differential temperature can vary through the heat exchanger. A mean value, LTMD, is used for calculation. It is called Dtm in the general formula above. It can be calculated by following formula, using the denominations in figure 2 [1]

Figure 2

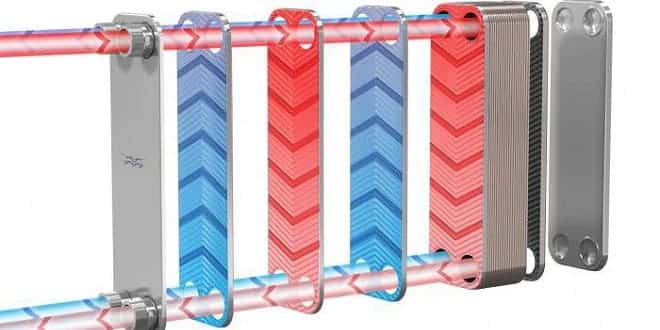

Most heat treatment of dairy products is carriedout in plate heat exchangers. The plate heat exchanger (often abbreviated PHE) consists of a pack of stainless steel plates clamped in a frame. The frame may contain several separate plate packs – sections – in which different stages of treatment such as preheating, final heating and cooling take place. The heating medium is hot water, and the cooling medium cold water, icewater or propyl glycol, depending on the required product outlet temperature. The plates are corrugated in a pattern designed for optimum heat transfer. The plate pack is compressed in the frame. Supporting points on the corrugations hold the plates apart so that thin channels are formed between them. The liquids enter and leave the channels through holes in the corners of the plates. Varying patterns of open and blind holes route the liquids from one channel to the next. Gaskets round the edges of the plates and round the holes form the boundaries of the channels and prevent external leakage and internal mixing [3]

Flow patterns

The product is introduced through a corner hole into the first channel of the section and flows vertically through the channel. It leaves at the other end through a separately gasketed corner passage. The arrangement of the corner passages is such that the product flows through alternate channels in the plate pack. The service (heating or cooling) medium is introduced at the other end of the section and passes, in the same way, through alternate plate channels. Each product channel consequently has service medium channels on both sides. For efficient heat transfer the channels between the plates should be as narrow as possible; but both flow velocity and pressure drop will be high if a large volume of product must pass through these narrow channels. Neither of these effects is desirable and, to eliminate them, the passage of the product through the heat exchanger may be divided into a number of parallel flows.

In figure the blue product flow is divided into two parallel flows which change direction four times in the section. The channels for the red heating medium are divided into four parallel flows which change direction twice.

This combination is written as 4 x 2 / 2 x 4, i.e. the number of passes times the number of parallel flows for the blue product over the number of passes times the number of parallel flows for the red service medium. This is called the grouping of the plates [4].

HTST Pasteurisation

HTST is the abbreviation of High Temperature Short Time. The actual time/temperature combination varies according to the quality of the raw milk, the type of product treated, and the required keeping properties [4].

Milk

The HTST process for milk involves heating it to 72 – 75°C with a hold of 15 –20 seconds before it is cooled. The phosphatase enzyme is destroyed by this time/temperature combination. The phosphatase test is therefore used to check that milk has been properly pasteurised. The test result must be negative: there must be no detectable phosphatase activity [4].

PROCEDURE

1. Raw milk was poured to receiving tank (balance tank in dairy industry).

2. Then flow rates of milk and water were adjusted to 1000ml/min and 405 ml/min respectively.

3. Then,plate heat exchanger was set up until temperature of heating section reached to 69.9ºC by controlling temperature with thermocouple.

4. Until temperature of plate heat exchanger raised to 69.9ºC , raw milk was circulated around tank and heating medium so that temperature of raw milk was raised to around 35-40ºC.

5. When temperature of milk reached to 72ºC,pasteurization started

6. Pasteurized milk was sent to holding tube to be held for 15 seconds

7. Then pasteurized milk cooled to ambient temperature with cooling water

8. After pasteurization of milk,cleaning of plate heat exchanger was carried out with application of CIP (cleaning in place system)

Steps of CIP

1. Rinsing with warm water for about 10 minutes.

2. Circulation of an alkaline detergent solution (0.5 – 1.5%) for about

3. 30 minutes at 75°C.

4. Rinsing out alkaline detergent with warm water for about 5 minutes.

5. Circulation of (nitric) acid solution (0.5 – 1.0 %) for about 20 minutes at

6. 70°C.

7. Post-rinsing with cold water.

8. Gradual cooling with cold water for about 8 minutes

RESULTS AND CALCULATION

T1= Exit temp. of milk from holding section= 72,2°C

T2= exit temp. of milk from regeneration section= 60,9°C

T3= cold water in temp = 18,7°C

T4= hot water in temp= 78°C

T5= exit temp of milk from cooling section= 36,5°C

T6= exit temp of cold water out=24,3°C

Tx=temp of milk out from regeneration=?

Ty= temp of cold water out from heating section=?

Tr= temp of raw milk at the beginning=?

Diameter of tube= 7,086*10-3 m

Plates number= cooling:5 ; regeneration:19 ; heating:15

Flow rate of milk=405ml/min=6.75*10-6 m3/sec

Flow rate of water=1000ml/min=16.6*10-6m3/sec

F=15sec

Area of a plate= 5,676*10-3m^2

1-) U for each section;

a) U for cooling section

Qwater=Qmilk

Mw.cpw.(T6-T3)=mm.cpm.(Tx-T5)

(16,6*10-6m3/s)*(1000kg/m3)*(4200J/kg.°C)*(24,3-18,7)°C =

(6,75*10 6m3/s)*(1030kg/m3)*(3900J/kg.°C)*(Tx-36,5)

Tx=50,9°C

Qm=m.cp.(Tx-T5)=U.A.Tlm

A=5*5,676*10-3m2

Tlm=21,94°C

(6,75*10-6)*(1030)*(3900)*(50,9-36,5)=Uc*(5*5,676*10-3)*(21,94)

Uc=627,07J/s.°C.m2

b) U for regeneration section

(Qmilk)preheating= (Qmilk)precooling

(T2-Tr)=(T1-Tx)

(60,9-Tr)=(72,2-50,9)

Tr=39,6

Qm=m.cp.(T1-Tx)=Ur.A.Tlm

6,75*10-6*1030*3900*(72,2-50,9)=Ur*19*5,676*10-3*11,3

Ur=474J/s°Cm2

c) U for heating

16,6*10-6*1000*4200*(78-Ty)=6,75*10-6*1030*3900*(72,2-60,9)

Ty= 73,6°C

Tlm=8,84°C

Qm=m.cp.(T1-T2)=Uh.A.ΔTlm

6,75*10-6*1030*3900*(72,2-60,9)=Uh.15*5,676*10-3*8,84

Uh=407,44J/s°Cm2

2-) total overall heat tr. coefficient;Ut

Qt=mcp(Tpast.-Traw)=Ut.Ar+h.(Tr-T5)

Ut=1477,5W/m2°C

3-) amount of heat recovered

a) heating section

39,6—-60,9—72,2

(72,2-60,9)/(72,2-39,6)*100

=%34,66

b) cooling section

72,2——50,9—-36,5

(72,2-50,9)/(72,2-36,5)*100

=%59,66

4-) % heat exchanged in regeneration section

QR/QT *100

QR = m*cp*ΔTr / m*cp*ΔTt *100 = (60,9-39,6)/(72,2-39,6) = 65.34%.

5-) Length of holding tube=L

r=1030kg/m^3

m=2,12*10^-3 kg/m.s

D= 7,086*10^-3m

V=6,75*10^-6/3,94*10^-5 m/s

Nre=588

Vmax=flow rate/A

=0,171m/s

L=F.Vmax

L=15s.0,171m/s

L=2,5m

DISCUSSION

LITERATURE

1. Dictionary of Dairy Technology (English, French, German, Spanish, compiled by International Dairy Federation (IDF), Brussels, Belgium Elsevier Scientific Publishing Company, Amsterdam/Oxford/New York, 1983

2. A Dictionary of Dairying (by J.G. Davis Leonard Hill, London, UK)

3. Fundamentals of Dairy Chemistry (Editied by B.H. Webb and A.Johnson

The AVI Publishing Company Inc., Westport, Connecticut, USA)

4. Developments in Dairy Chemistry, Volume 1 – 4 by P.F. Fox (by P.F. Fox Applied Science Publishers, London and New York )

…