Gıda Uygulamaları Laboratuarı

-

Tray Drier ( Kadir DAĞDEVİREN )

PURPOSE: The aim of the this experiment was to learn working principles of batch type of tray dryer its application in drying of wet marrow to obtain information about falling rate period, constant rate period, equilibrium moisture content, free moisture content of drying periods, and total drying time was calculated according to results which measured during the experiment on the tray dryer. THEORY: Drying is defined as that unit operation which converts a liquid, solid or semi-solid food material into a solid product of significantly lower moisture content. Drying is…

-

Tray Drier ( Özcan NALBANT )

Tray dryers and their developed forms, tunnel dryers are equipments, which found many applications in food operation operations during dehydration of foods. All the drying characteristics of foods can be observed in these equipments. A typical drying procedure was applied with tray dryer to investigate properties of tray dryers, its advantages or disadvantages, drying kinetics of foods that are dried in tray dryers. For these purposes, equilibrium moisture content, drying rate, mathematical and experimental drying time were calculated with some engineering formulas. Wet pepper was used as sample for this…

-

Tray Dryer ( Hakan MAVİŞ )

A range of technologies are used for food drying which include tray and tunnel dryers, spray, roller and freeze dryers. With the exception of tray dryers none of these are appropriate, in terms of cost and output, for use by small and medium enterprises. While sun drying on trays or in solar dryers can be considered as tray drying the term is normally applied to small industrial systems with some form of air heater and a fan to pass air over the product being dried. While small tray dryers are…

-

Tubular Heat Exchanger

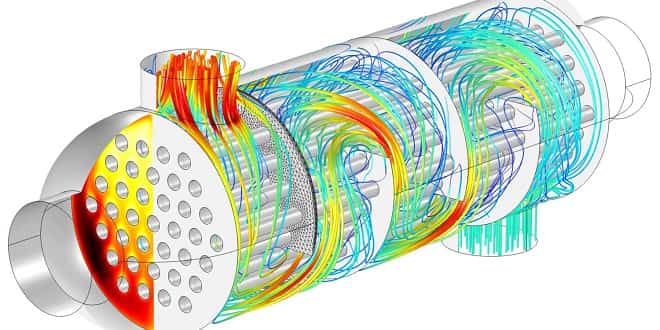

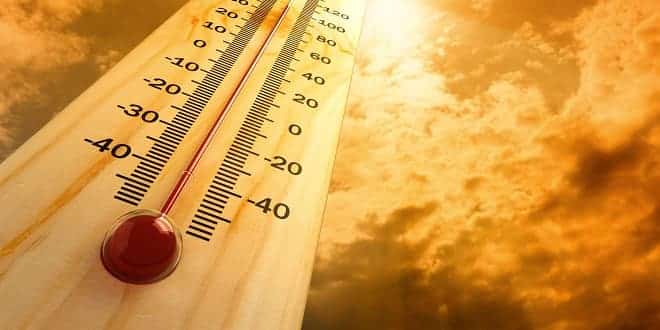

In the work of Chemical engineering, heat exchanger is an essential part of a unit operation. Double pipe heat exchanger is an excellent example to demonstrate the principle of heat transfer using a simple-structured equipment. In this experiment we worked on concentric tube heat exchanger. The principle of this device is to cool a hot fluid or to heat a cold fluid by using countercurrent or cocurrent flow. The external surface of the exchanger is insulated to minimize losses in the system, hot water is fed through the iner pipe,…

-

Tubular Heat Exchanger ( Canan ÇİÇEK )

Shell and tube heat exchangers (STHE’s) are apparatuses in which the heat exchange between hotter and colder fluid is done. Fluid flowing through tubes is called – tube fluid, and fluid flowing around tube bundle is called – shell side fluid. Baffles, placed in shell side space, are providing the cross flow direction of shell side fluid and so the more intensive heat exchange between fluids could be realized. Besides, baffles are carriers of tube bundle, which helps them to decrease the deflection in horizontal and vibrations in horizontal and…

-

Tubular Heat Exchanger ( Kerime Dilek YILDIZ )

Heat exchangers are devices used to transfer heat between two or more fluid streams at different temperatures. Heat exchangers find widespread use in power generation, chemical processing, electronics cooling, air-conditioning, refrigeration, and automo- tive applications.The simple type of heat exchanger is double pipe heat exchanger. In this experiment, the working princples a concentric tube heateexchanger operating under parallel and counter flow conditions was observed and the effect of hot water flow rare and hot water temperature variation the performance characteritics of a concentric heat exchanger were observed. …

-

Tubular Heat Exchanger ( Serpil HAKAN )

A heat exchanger is a heat transfer device whose purpose is the transfer of energy from one moving fluid stream to another moving fluid stream. Heat exchanger is a device in which heat is transferred between the hot and cold medium. The overall energy transfer is dictated by thermodynamics and the First Law. Various heat transfer equipment is a common sight in many industrial plants and has a broad range of application in power stations, chemical and petrochemical processing plants, building heating and air conditioning, refrigeration systems, automotive industry, marine…

-

Ayırma İşlemleri – Ekstraksiyon ( Prof. Dr. Mualla ÖNER )

EKTRAKSİYON Grafiksel Çözüm İki karışımın birbiri ile teması sonucu oluşan yeni karışımın bileşiminin saptanması Kimya Mühendisliği proseslerinde sık karşılaşılan bir durumdur. İki karışımın eklenmesiyle oluşan yeni karışımın bileşimi, orijinal karışım bileşimlerini birleştiren doğru üzerinde yer alır. Bu kural grafiksel toplam kuralı olarak bilinir. Sonuç karışımın doğru üzerindeki yerinin saptanması için ters kaldıraç kuralı kullanılır. …