Gıda Uygulamaları Laboratuarı

-

Pasteurization of Milk By Plate Heat Exchanger

PASTEURIZATION The process of heating EVERY PARTICLE of milk and milk products to the minimum required TEMPERATURE (for that specific milk or milk product), and holding it continuously for the minimum required TIME in equipment that is PROPERLY DESIGNED and OPERATED. Pasteurization has also been described as a heat treatment or thermal process used to kill part but not all of the vegetative microorganisms present in the food. …

-

Plate and Frame Filters

Filtration is a physically or mechanically separation process in which suspended solid particles in a fluid are removed by using a porous medium that retain the particles as a cake and passes the clear filtrate. The porosity distribution and filtrate production during cake filtration in a plate-and-frame filter press were simulated mathematically. The model considered filtration that occurs after the filling process, not filtration that occurs as the suspension fills the cell. Operational equations and theoretical calculation K, s, C, m were developed for a plate-and-frame press. …

-

Plate and Frame Filtration

The porosity distribution and filtrate production during cake filtration in a plate-and frame filter press were simulated mathematically. The model considered filtration that occurs after the filling process, not filtration that occurs as the suspension fills the cell. Governing equations for the temporal porosity distribution were developed for a plate and- frame press. The governing equations were solved numerically. Appropriate initial and boundary conditions were determined based on characteristics of the plate-and-frame press and of the suspension properties The purpose of this experiment was to learn how plate-and-frame filtrate machine to work and also to determine the…

-

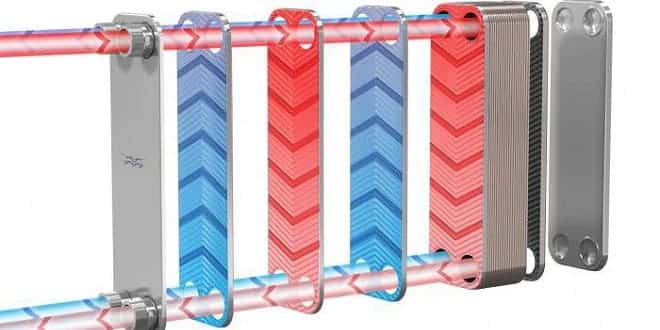

Plate Heat Exchanger

ABSTRACT Pasteurization is a killing method of pathogenic microorganisms e.g mycobacterium tuberculoses , salmonella by application of heat at 62ºC for 30 minutes or 72ºC for 15 seconds. In this experiment, raw milk was pasteurized by using plate heat exchanger at 72ºC for 15 seconds and overall heat transfer coefficient of regeneration,cooling and heating mediums was calculated.Effectiveness of plate heat exchanger was measured by using datas obtained from experiment.Microbial succession of plate heat exchanger was investigated by using methylene blue indicator for color changes because of binding tendency of methylene…

-

Principle of Plate and Frame Filter Press

ABSTRACT: In this experiment , our aim was to learn the working principle of plate and frame filter press briefly and to gain knowledges about filtration process and types of filters with their applications in food industry.We filtrated the mint and water mixture under two different pressures.The most significant point of our discussion is to check the effect of increased pressure at filtration rate and calculation of constants such as m,c,k,s from our data. CONTENTS: INTRODUCTION MATERIALS PROCEDURE CALCULATIONS RESULTS AND DISCUSSION CONCLUSIONS REFERENCES APPENDICES ….

-

Rheology of Sumac Concentration

Abstract In this experiment, the rheological properties of sumac concentrate was determined with different brix values in different temperature ranges (10, 20, 30 oC) and obtain some data related with shear stress, shear rate and viscosity. The graphs which is plotted according to these data was interpreted by Power law and Arrhenius equation and we have found that sumac concentrate shows Non-Newtonion fluid behaviour. …

-

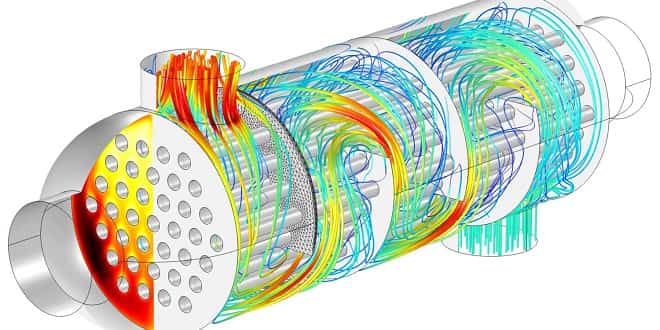

Shell and Tube Heat Exchanger

Shell and tube heat exchangers are among the more confusing pieces of equipment for the process control engineer. The principle of operation is simple enough: Two fluids of different temperatures are brought into close contact but are prevented from mixing by a physical barrier. The temperature of the two fluids will tend to equalize. By arranging counter-current flow it is possible for the temperature at the outlet of each fluid to approach the temperature at the inlet of the other. The heat contents are simply exchanged from one fluid to…

-

Solid Liquid Extraction ( Ali OK )

Firstly, some amount of dried hazelnut sample was taken and put into the mixer to grind and to reduce the particle size. Then cloth bag which we put our sample and funnel were weighted. Our sample was weighted as 259,1g.Top of the cloth bag was tied up strongly and put into extractor vessel. After that the solvent pump was adjusted to 10 ml/min and temperature of solvent to 40-42 ◦C. The extractor was worked for 20 min. At the end of the period cloth bag was taken and weighted. Our…