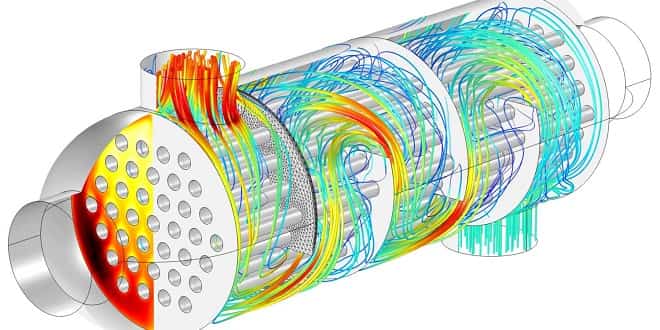

Shell and tube heat exchangers (STHE’s) are apparatuses in which the heat exchange between hotter and colder fluid is done. Fluid flowing through tubes is called – tube fluid, and fluid flowing around tube bundle is called – shell side fluid. Baffles, placed in shell side space, are providing the cross flow direction of shell side fluid and so the more intensive heat exchange between fluids could be realized. Besides, baffles are carriers of tube bundle, which helps them to decrease the deflection in horizontal and vibrations in horizontal and vertical units. STHE’s usually have combined fluid flow, which means that there is parallel in one, and counter flow in other part of the exchanger. These apparatuses are usually denoted as m-n STHE’s, where m is the number of fluid passes through the shell, and n is the number of fluid passes through the tube bundle [9, 14]. If the STHE is with so called “full tube bundle”, the shell side fluid flows through baffle cuts along the tubes. On the shell side, there is not just one stream, beside a main cross-flow stream the four leakage or bypass streams exist as a result of design type: baffle to tubes, baffle to shell and tube bundle to shell gaps (tube – to – baffle hole leakage stream, bundle bypass stream, pass – partition bypass stream and baffle – to – shell leakage stream).

One of STHE manufacturer’s main goals is to improve their exploitation reliability and efficiency. Two approaches in STHE design improving are possible: experimental investigation and numerical investigations. Experimental investigations are very expensive and long lasting, because of shell side complex geometry. Numerical simulations can be used to check the old design and to develop a new more efficient STHE design. Shell side flow is almost always turbulent since tube bundle and baffles are very nice turbulent promoters.

Character of flow around some tube rows in tube bundle is strongly influenced by tube layout (square, rotated square, triangular, rotated triangular, circular).

Character of flow around the tubes has a direct influence on heat exchange between fluids.

Problem is more complex if heat transfer is simultaneous with phase change. Since the detailed measurements of turbulent characteristics of shellside fluid flow are almost impossible, the calculated fields of pressure, velocity, temperature as well as turbulent characteristics are of great significance in explaining very complex thermal and flow processes in STHE’s.

Basically, one can conclude that heat transfer between fluids in STHE’s is highly influenced not only by thermal and flow quantities, such as inlet temperatures and velocities, but also with baffle cut size, baffle spacing, size of inlet and outlet zones and number of baffles.

To investigate influence of mentioned parameters, thermal, flow and geometric, or by other words, to find the “apparatus response” to thermal and fluid quantities and shell side geometry, in steady regime, by experimental and numerical methods, it was necessary to conceive of one compact experimental STHE.

…