INTRODUCTION

The term “lipid” refers to a group of compounds that are soluble in water, but show variable solubility in a number of organic solvents. The lipid content of food determined by extraction with one solvent may be quite different from the lipid content as determined with another solvent of different polarity.

Fat content is determined by often by solvent extraction methods, but it is also can be determined by non-solvent wet extraction methods and by instrumental methods that rely on the physical and chemical properties of lipids.

The method of choice depends on a variety offactors, including the nature of the sample, the purpose of the analysis and instrumentation available.

A Soxhlet extractor is a piece of laboratory apparatus invented in 1879 by Franz von Soxhlet. It was originally designed for the extraction of a lipid from a solid material.

This experiment so uses a soxhlet method to determine the lipid contents of plant & animal tissues.

The Soxhlet method for determining crude fat content is a lengthy process requiring up to a day for a single analysis. The solvent extraction step alone

takes six hours.

The method is therefore not favoured for routine testing purposes in the meat industry, rather it is used as a standard reference method.

In principle, fat is extracted, semi continuously, with an organic solvent.

Solvent is heated and volatized then is condensed above the sample.

Solvent drips onto the sample and soaks it to extract the fat. At 15-20 min interval, the solvent is siphoned to the heating flask, to start the process again.

Fat content is measured by weight loss of sample or weight of fat removed.

OBJECTIVE

1. To extract fat from various plant & animal tissues by an exhaustive extraction using a Soxhlet extractor

2. To determine percent of fat content in a food sample by weight in a sample.

3. To study the function of extraction process by Soxhlet extractor

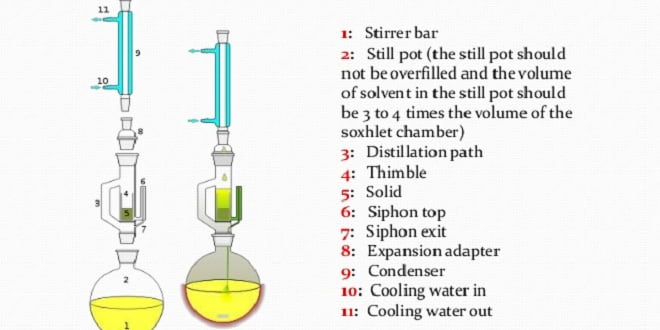

1: Stirrer bar/anti-bumping granules

2: Still pot (extraction pot) – still pot should not be overfilled and the volume of solvent in the still pot should be 3 to 4 times the volume of the soxhlet chamber.

3: Distillation path

4: Soxhlet Thimble

5: Extraction solid (residue solid)

6: Syphon arm inlet

7: Syphon arm outlet

8: Expansion adapter

9: Condenser

10: Cooling water in

11: Cooling water out

Schematic diagram of a Soxhlet extractor.

THE SOXHLET EXTRACTOR

Continuous extraction of a component from a solid mixture.

Boiling solvent vapors rise up through the larger side-arm

Condensed drops of solvent fall into the porous cup, dissolving out the desired component from a solid mixture

When the smaller side-arm fills to overflowing, it initiates a siphoning action.

The solvent, containing the dissolved component, is siphoned into the boiler below

Residual solvent then drains out of the porous cup, as fresh solvent drops continue to fall into the porous cup.

. . . and the cycle repeats . . .

It should look something like THIS: (only much SLOWER)

This program will re-start in one minute. To terminate, press Esc

…