UNIVERSITY of GAZIANTEP

FACULTY of ENGINEERING

FOOD ENGINEERING

FOOD ADDITIVE

ADDITIVES IN MARGARINE

SUBMITTED by ZEYNEP YILMAZ

SUBMITTED to HUSEYIN BOZKURT

DATE 17.05.2007

REFERENCES ANDERSEN, A.J.C. MARGARINE, 1954

FOOD ADDITIVES

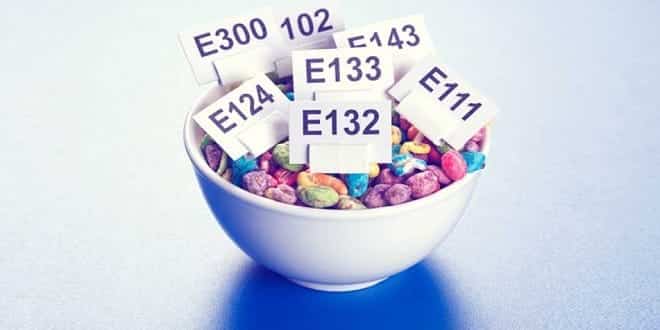

Food additives play a vital role in today’s bountiful and nutritious food supply. They allow our growing urban population to enjoy a variety of safe, wholesome and tasty foods year-round. And, they make possible an array of convenience foods without the inconvenience of daily shopping.

Although salt, baking soda, vanilla and yeast are commonly used in foods, today many people tend to think of any additives added to foods as complex chemical compounds. All food additives are carefully regulated by federal authorities and various international organizations to ensure that foods are safe to eat and are accurately labeled. The purpose of this brochure is to provide helpful background information about food additives, why they are used in foods, and how regulations govern their safe use in the food supply.

ADDITIVES

Antioxidants

Antioxidants prevent fats and oils from going rancid due to oxidation of the unsaturated fatty acid radicals in the triglycerides of which fat is composed. Antioxidants which occur naturally in fats tend to prevent the oxidative changes which produce rancidity. The most effective antioxidants are vitamin E.

Emulsifiers

When oil is added to water, it forms a separate layer above the water. The oil and water do not dissolve in each other and are said to be immiscible. If oil and water are shaken together these two liquids become dispersed in each other and an emulsion is formed. If the liquid is allowed to stand then it reverts back to the two layers, therefore this form of emulsion is termed an unstable emulsion.

Emulsions are described as being either oil in water (O/W) or water in oil (W/O) emulsions. Margarine is termed as water in oil emulsion as small droplets of water are dispersed through the oil. In order for the oil and water to form a stable emulsion a third substance is called an emulsifying agent or emulsifier is used. In the case of margarine, the emulsifying agents most commonly used are proteins e.g. casein, lecithin or glycerol monostearate (GMS).

Stabilizers

Stabilizers are sometimes used to maintain the emulsion once it has been formed.

Colourings

Colourings are added to replace colour lost during processing. The colourings are most commonly used is Beta Carotene.

Preservatives

Preservatives are used to extend the products shelf life and to prevent microbial growth which can cause food spoilage. Products most commonly used in the manufacture of margarine.

MARGARINE PRODUCTION

Margarine is a food in the form of plastic or fluid emulsion, which is mainly type of water/oil production. Margarine is a fatty food closely resembling butter. The fat of margarine is not derived from milk fat, however at most only to a minor extent.

The term margarine is derived from Greek word ‘margarites’, meaning pearl subsequently shown to be a mixture of stearic and palmitic acids.

Margarine is now made from a water-in-oil emulsion, the aqueous phase being fat free milk and the oil phase being a blend of different oils. The two phases are mixed together and, with the aid of suitable emulsifiers, a stable emulsion is formed. The emulsion is processed until it forms a solid product having the desired consistency.

The oil blend

The selection of oils for margarine is made by the manufacturer with regard to cost, quality, and desired properties in margarine. Today; soybean, sunflower, palm, rapeseed, cotton seeds have been the most important vegetable oils used, partly in view of their availability.

The aqueous phase

About 16-18% of margarine consists of an aqueous milk preparation. In the production of aqueous phase pasteurized fresh milk or reconstituted dry milk is subjected to a ripening process. During this process diacetyl and aroma giving substances are developed.

Production

The first step in the production of margarine is the preparation of the fat blend. The fat blend may contain natural crude fats and processed fats such as fractionated, hydrogenated or interesterified mixtures. It is first refined and deodorized and then emulsified with the aqueous phase, emulsifiers being generally added at this point. Other ingredients such as vitamins, flavoring and coloring agents are usually incorporated just before emulsification.

Margarine is moulded and packed directly from the production unit. Rectangular 250 g locks are a common unit while the softer margarines are packed directly into plastic tubes.

The term margarine no longer describes a single product but a whole range of products that provide a wide variety of different blends of oils and flavors to meet every need and taste.

Additives are used in the manufacture of margarine and spreads to improve their keeping properties, appearance and stability. A number of ingredients and auxiliary materials are used in margarine, partly for taste and aroma, partly to give various physical and nutritional characteristics.

The following substances may be added to margarine:

Vitamins

Vitamin A and its esters

Vitamin D

Vitamin E and its esters

0ther vitamins

Maximum and minimum levels for vitamins A, D and E and other vitamins should be laid down by national legislation in accordance with the needs of each individual country including, where appropriate, the prohibition of the use of particular vitamins.

Sodium chloride

Sugars 2

Suitable edible proteins

FOOD ADDITIVES

Colours

Beta-carotene

Annatto extracts (calculated as total bixin or norbixin)

Curcumin or Turmeric (calculated as total Curcumin)

Beta-apo-8′-carotenal

Methyl and ethyl esters of beta-apo-8′

Carotenoic acid

Flavors

Natural flavors and their identical synthetic equivalents, except those which are known to represent a toxic hazard, and other synthetic flavors approved by the Codex Alimentarius Commission are permitted for the purpose of restoring natural flavor lost in processing or for the purpose of standardizing flavor, as long as the added flavor does not deceive or mislead the consumer by concealing damage or inferiority or by making the product appear to be of greater than actual value.

Emulsifiers

Mono- and diglycerides of fatty acids Limited by GMP

Mono- and diglycerides of fatty acids esterified with the following acids:

acetic; acetyltartaric; citric; lactic; tartaric, and their sodium and calcium salts

Lecithins and components of commercial

Polyglycerol esters of fatty acids

1, 2-propylene glycol esters of fatty acids

Esters of fatty acids with polyalcohols other than glycerol:

Sorbitan monopalmitate

Sorbitan monostearate

Sorbitan tristearate

Sucrose esters of fatty acids (including

sucroglycerides)

Preservatives

Sorbic acid and its sodium, potassium and calcium salts

Benzoic acid and its sodium and potassium salts expressed as the acids

Antioxidants

Propyl gallate 100 mg/kg

Butylated hydroxytoluene (BHT) 75 mg/kg

Butylated hydroxyanisole (BHA) 175 mg/kg

Any combination of propyl gallate, BHA,BHT

Natural and synthetic tocopherols 500 mg/kg Ascorbyl palmitate ) 500 mg/kg individually or in combination Ascorbyl stearate )

Dilauryl thiodipropionate 200 mg/kg

Antioxidant synergists

Citric acid Limited by GMP

Sodium citrate Limited by GMP

Isopropyl citrate mixture

Phosphoric acid

Monoglyceride citrate

Acidity regulators

Citric and lactic acids and their potassiumand sodium salts

L-tartaric acid and its sodium and sodium/potassium salts